SECONDARY BIOLOGICAL PROCESSES

Secondary biological processes are used for biological removal of up to about 90% of the organic matter in wastewater following primary treatment operations. WE can supply suspended growth, attached growth, membrane bioreactors and BAFs, systems for both new and retrofit applications, standalone process or package treatment plants. WE, through our manufacturers, can supply single source point of responsibility backed in many cases with performance bonds to give you the piece of mind to know that your system will perform as designed to meet or exceed your treatment requirements.

Secondary biological processes are used for biological removal of up to about 90% of the organic matter in wastewater following primary treatment operations. WE can supply suspended growth, attached growth, membrane bioreactors and BAFs, systems for both new and retrofit applications, standalone process or package treatment plants. WE, through our manufacturers, can supply single source point of responsibility backed in many cases with performance bonds to give you the piece of mind to know that your system will perform as designed to meet or exceed your treatment requirements.

SUSPENDED GROWTH SYSTEMS

Aero-Mod Wastewater Process Solutions

The Sequox® Process

The Sequox® Process with our innovative DO2ptimizer control strategy offers optimal energy efficiencies. It has more turn down for under loaded plants than ever before. The control philosophy allows the plant to mimic the actual organic loading coming to it.

Cost Effective Nitrogen Removal

The patented SEQUOX Nitrogen Removal Process is the latest innovation for biological nitrogen removal from wastewater. Even if nitrogen removal is not the primary objective, the SEQUOX process results in sufficient process improvements and energy savings to make it cost effective.

Superior Effluent Quality

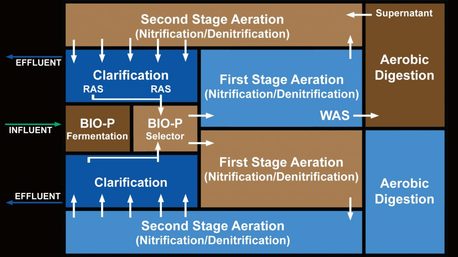

SEQUOX offers the benefits of sequencing aeration with the reliability of continuous clarification, resulting in consistently superior effluent quality with total nitrogen levels of 3 mg/L. With the inclusion of the Bio-P process, phosphorus levels of 1 mg/L or less are possible. To achieve better solids settling, SEQUOX incorporates a selector tank to provide a preconditioning of raw wastewater that inhibits filamentous growth. The process is energy efficient and has a small footprint, lowering capital costs.

Innovative High Performance Clarifier

The patented, low-maintenance, operator friendly ClarAtor provides clarification to the Aero-Mod system. It features no moving parts below the water, a uniform distribution and collection of the flow, and the unique ability to regulate the effluent flow rate. Its unique flow regulation system even provides in-basin surge storage.

The Sequox® Process

The Sequox® Process with our innovative DO2ptimizer control strategy offers optimal energy efficiencies. It has more turn down for under loaded plants than ever before. The control philosophy allows the plant to mimic the actual organic loading coming to it.

Cost Effective Nitrogen Removal

The patented SEQUOX Nitrogen Removal Process is the latest innovation for biological nitrogen removal from wastewater. Even if nitrogen removal is not the primary objective, the SEQUOX process results in sufficient process improvements and energy savings to make it cost effective.

Superior Effluent Quality

SEQUOX offers the benefits of sequencing aeration with the reliability of continuous clarification, resulting in consistently superior effluent quality with total nitrogen levels of 3 mg/L. With the inclusion of the Bio-P process, phosphorus levels of 1 mg/L or less are possible. To achieve better solids settling, SEQUOX incorporates a selector tank to provide a preconditioning of raw wastewater that inhibits filamentous growth. The process is energy efficient and has a small footprint, lowering capital costs.

Innovative High Performance Clarifier

The patented, low-maintenance, operator friendly ClarAtor provides clarification to the Aero-Mod system. It features no moving parts below the water, a uniform distribution and collection of the flow, and the unique ability to regulate the effluent flow rate. Its unique flow regulation system even provides in-basin surge storage.

Fluidyne Corporation ISAM (Integrated Surge Anoxic Mix)

System Components System Components

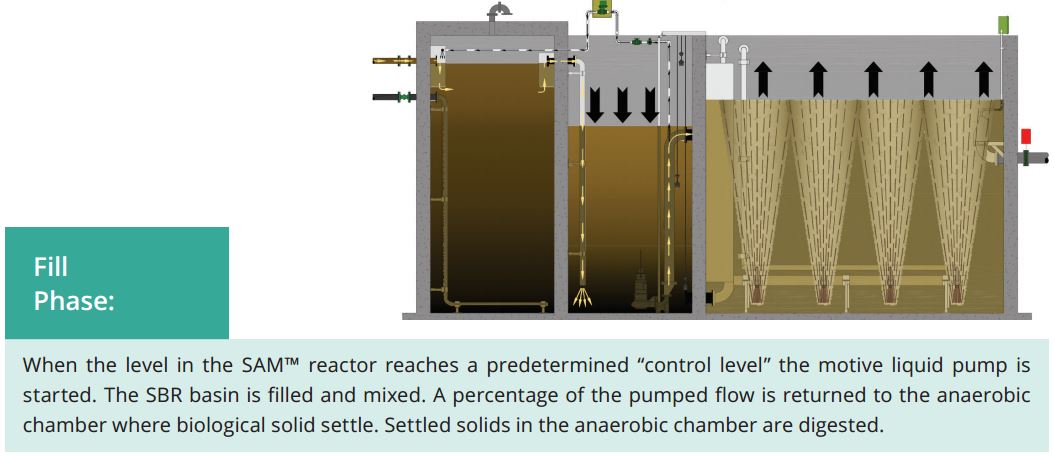

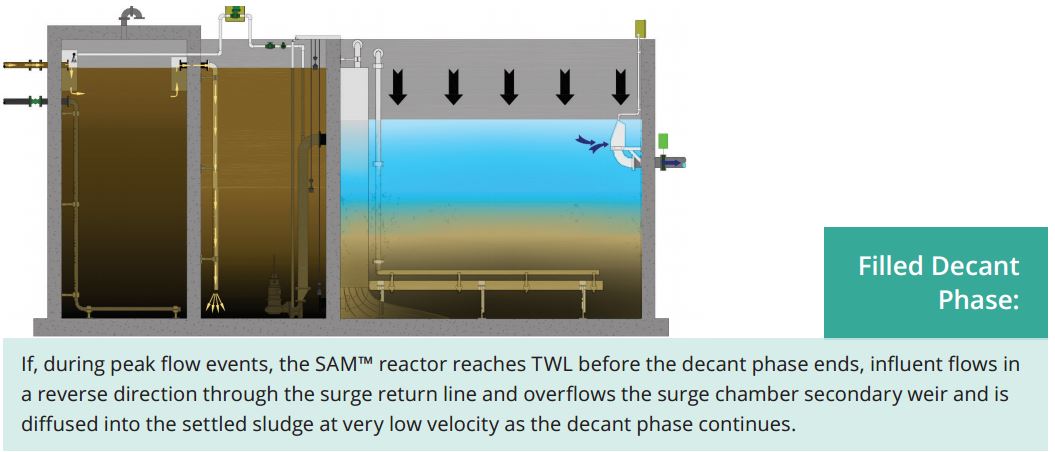

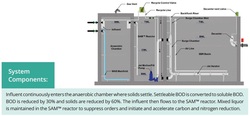

The ISAM™ is a total treatment system incorporating BOD, TSS and nitrogen removal along with sludge reduction in an integrated system. Raw (crude) sewage enters a covered anaerobic reactor for pretreatment, sludge thickening and sludge destruction. Complex organic solids undergo hydrolysis to simpler soluble organics which pass to the surge anoxic mix (SAM™) tank.

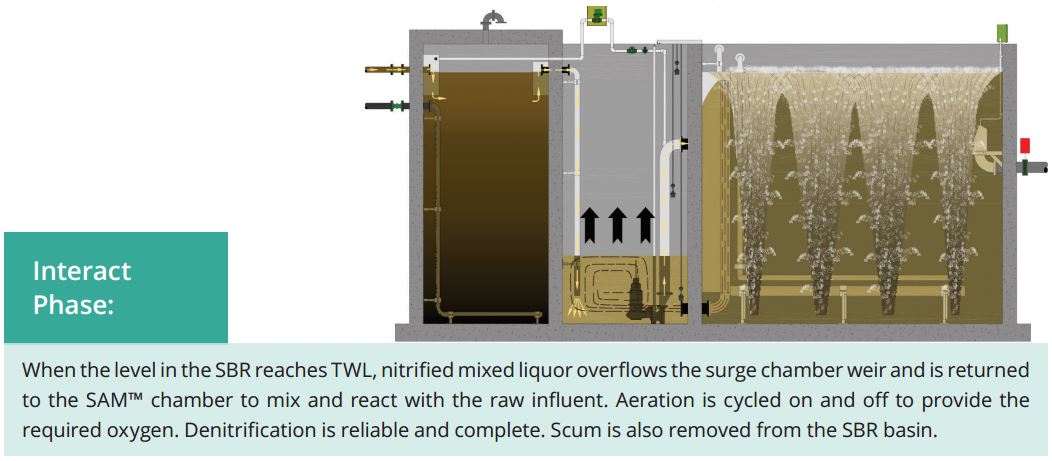

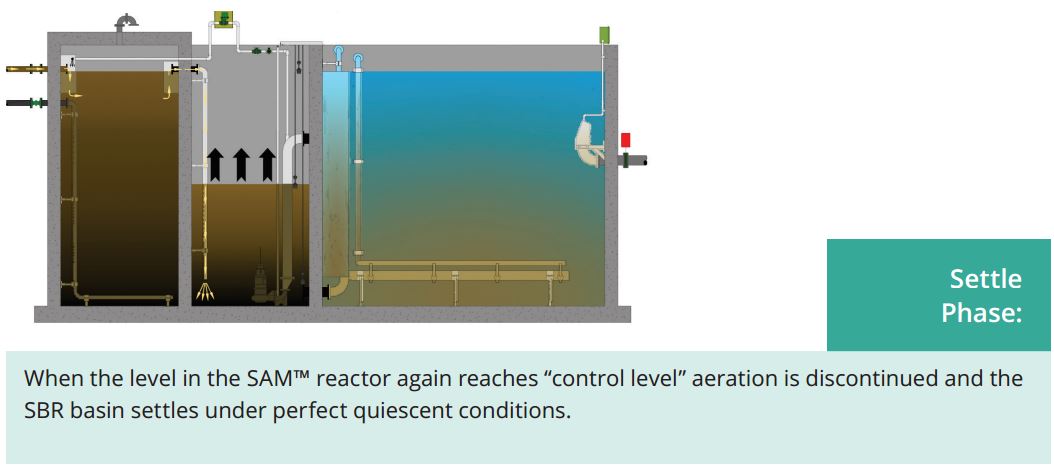

A TOTALLY NEW CONCEPT IN SBR DESIGN In operation, all influent flow enters the anaerobic basin where influent solids are allowed to settle much like a primary clarifier. Elimination of primary solids in the anaerobic basin allows for much smaller SBR basins at equivalent SRT than conventional SBRs. The anaerobic selector also creates soluble carbon as a food source for biological nutrient removal through anaerobic conversion of settleable BOD to soluble BOD. The influent then flows to the SAM™ surge basin, or influent equalization basin. The surge basin provides flow and nutrient equalization to optimize treatment at the full range of flows and loadings. 100% ON-LINE STANDBY EQUIPMENT Fluidyne's prepackaged ISAM SBRs are furnished with spare mixing/fill pump and aerator assembly installed for 100% redundancy. REDUCES WASTE SLUDGE BY 75% The Fluidyne ISAM™ Sequencing Batch Reactor incorporates an anaerobic selector chamber with the SAM™ SBR. The anaerobic selector not only provides consistent phosphorous removal by subjecting the recirculated biomass to anaerobic conditions, forcing the release of phosphorous, but also creates soluble carbon as a food source for phosphorous removal through anaerobic conversion of settleable BOD to soluble BOD. Additionally, anaerobic sludge digestion occurs in the anaerobic selector chamber, reducing waste solids production by up to 75% for the entire secondary process. SEVERAL UNIQUE FEATURES Several unique feature of the Fluidyne ISAM™ SBR include odor control and scum skimming. Mixed liquor is maintained in the SAM™ tank to immediately react with incoming flow from the anaerobic chamber to suppress odors and initiate and accelerate carbon and nitrogen reactions. Mixed liquor is recycled from the top of the SBR tank effectively removing scum by use of proprietary flow and scum control system. In addition, nitrates are recycled to the SAM™ tank for effective and rapid denitrification. Denitrification reactions are accelerated in the presence of the unreacted carbon from the raw sewage entering the SAM™ tank. Aeration and energy requirements are reduced as nitrates are fully reduced to nitrogen gas in the SAM™ tank. Download the PDF Brochure HERE |