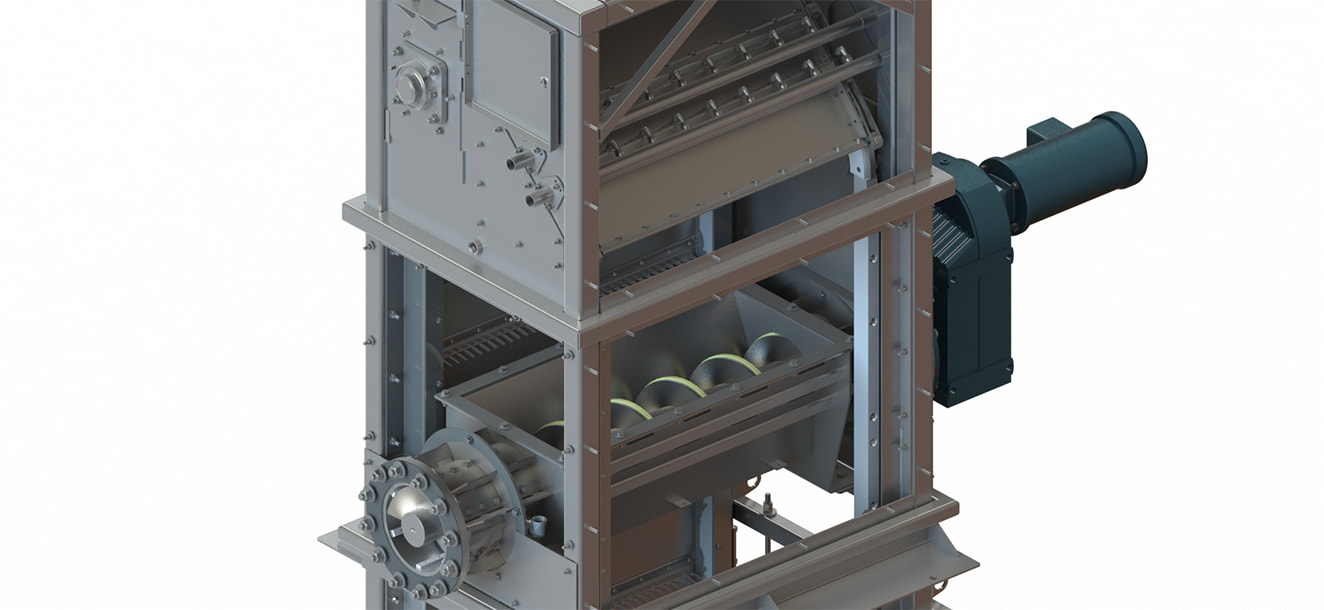

HEADWORKS SCREENS AND WASHER COMPACTORS

A plant’s headworks plays a crucial role in the pretreatment of influent for any wastewater treatment facility. It protects the operation of downstream equipment and enhances the efficiency of the overall wastewater treatment process. Because all of the debris in the plant starts at the headworks, proper screening and debris removal is imperative to the entire wastewater system. Pretreatment devices are designed to remove or reduce large solids like wood, cloth, paper and plastics, while also dealing with grit and excessive amounts of oil and grease.

Effective Headworks are the unsung hero and the heart of the treatment system. Good Headworks are essential to maintain an effectively run wastewater treatment facility. Preventing Grit from entering rotating equipment, removing solids that would otherwise settle in process equipment, and removing chunks of rags that will reform into ropes and entangle pumps, aeration headers and mixers is essential. Headworks needs are often unique to individual facilities and the wastewaters they treat. WE can provide the appropriate headworks equipment to meet your needs.

Effective Headworks are the unsung hero and the heart of the treatment system. Good Headworks are essential to maintain an effectively run wastewater treatment facility. Preventing Grit from entering rotating equipment, removing solids that would otherwise settle in process equipment, and removing chunks of rags that will reform into ropes and entangle pumps, aeration headers and mixers is essential. Headworks needs are often unique to individual facilities and the wastewaters they treat. WE can provide the appropriate headworks equipment to meet your needs.