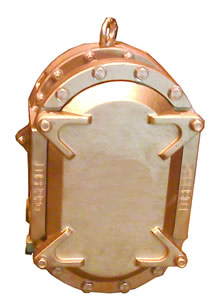

D-Series

LobePro’s D Series pumps are made from Type 2205 duplex steel and its cast equivalent, CD3mn for use in applications too corrosive for 316 stainless steel. These include applications with fluids containing chlorides, hydroxides, or H2S.

All LobePro CD3mn parts are solution annealed and passivated. This is very important to obtaining the best resistance to chloride corrosion, pitting and cracking. To learn more about duplex steel, visit Corrosive Engineering.

D Series pumps can also be manufactured to meet API 676 requirements in Oil and Gas applications.

Principle reason to use LobePro’s D Series for these applications includes:

LobePro’s D Series pumps are made from Type 2205 duplex steel and its cast equivalent, CD3mn for use in applications too corrosive for 316 stainless steel. These include applications with fluids containing chlorides, hydroxides, or H2S.

All LobePro CD3mn parts are solution annealed and passivated. This is very important to obtaining the best resistance to chloride corrosion, pitting and cracking. To learn more about duplex steel, visit Corrosive Engineering.

D Series pumps can also be manufactured to meet API 676 requirements in Oil and Gas applications.

Principle reason to use LobePro’s D Series for these applications includes:

- Reversable (can load, unload and backwash)

- Strong vacuum/Self-priming to 25 feet

- Handles air and fluid without damaging cavitation

- Low Shear

- Ability to pump thick, viscous fluids

- Steady, measured flow at constant pressure

- Can run dry

- Handles abrasives well

- ATEX Zone 2 Category 3 Rating

- Rapid Delivery

- Only a 3 feet NPSHR usually