BLOWERS

Sixty percent of the typical wastewater treatment plant electrical usage is for aeration (five times its closest competitor, pumping, at twelve percent). Proper aeration and blower selection is arguably one of the most important considerations at a wastewater plant. What type of blower is best for the customer? (centrifugal, PD or turbo). WE carry a full line of blowers and can help you select, size and layout the equipment for the most effective use of the end user's hard earned dollars. WE know aeration technologies.

Positive Displacement Blowers

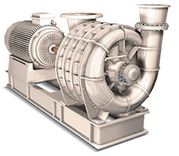

Centrifugal Blowers

|

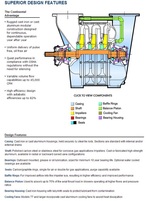

Continental's centrifugal multistage blowers are on the job — right now, and round the clock every day of the year — at municipal and industrial water and wastewater treatment plants throughout North America. The equipment has many critical tasks, including introducing precise quantities of oxygen into water tanks in order to allow bacteria to degrade any organic matter. These quiet, high quality blowers feature cast construction to withstand continuous duty, and are designed to maintain constant pressure with clean, dry, pulsation-free air delivery. Flow is widely variable through the use of a regulation butterfly valve at the inlet. Performance is optimized, energy consumption minimized, and maintenance costs are kept low. Few resources are as crucial as the world's water supply, and Continental Blower plays an indispensible role in keeping it pure.

Continental Blowers are built to handle:

|