AERATION DIFFUSERS

|

Stamford Scientific International, Inc. (SSI)

Whatever the application for your diffusers, WE have you covered. Whether you are looking for stainless, duck bill or membranes, complete system or diffusers, fixed or removable grid systems, Stamford Scientific produces the highest quality systems available on the market today. In a business environment where the others have sent production overseas, Stamford Scientific has brought their production to the US, producing products manufactured to the highest levels of quality available on the market today. Stamford Scientific manufactures disc diffusers with compression molded membranes. Standard materials are EPDM and fluoroelastomer layered EPDM. Compression molding ensures a diffuser with even specific gravity and uniform tear resistance. The tear resistance of a compression molded part is multidirectional, which is typically not found in injection molded unidirectional parts. Their manufacturing process ensures emulsifying fats cannot leech plasticizer and cause shrinkage and increase hardness, nor are their membranes at risk of flexure failure. SSI has the experience to recommend/design your complete aeration equipment. SSI offers complete design services, including 2D and 3D drawing generation and recommended layouts for different system configurations and processes. SSI has significant experience in process including empirical and lab data on alpha factors, oxygen transfer efficiency and fouling factors. This data can be applied to a variety of processes, such as extended aeration, BNR, SBR, MBR, MBBR as well as conventional activated sludge, in plug flow or complete mix tanks, and with or without channel velocity from flow boosters.They utilize in-house calculators as well as Biowin™ software to simulate system performance and to tweak their designs prior to presenting them to clients. |

|

Membrane Diffuser Materials and Coatings - The Secret to Maintining OTE and Minimizing Maintenance

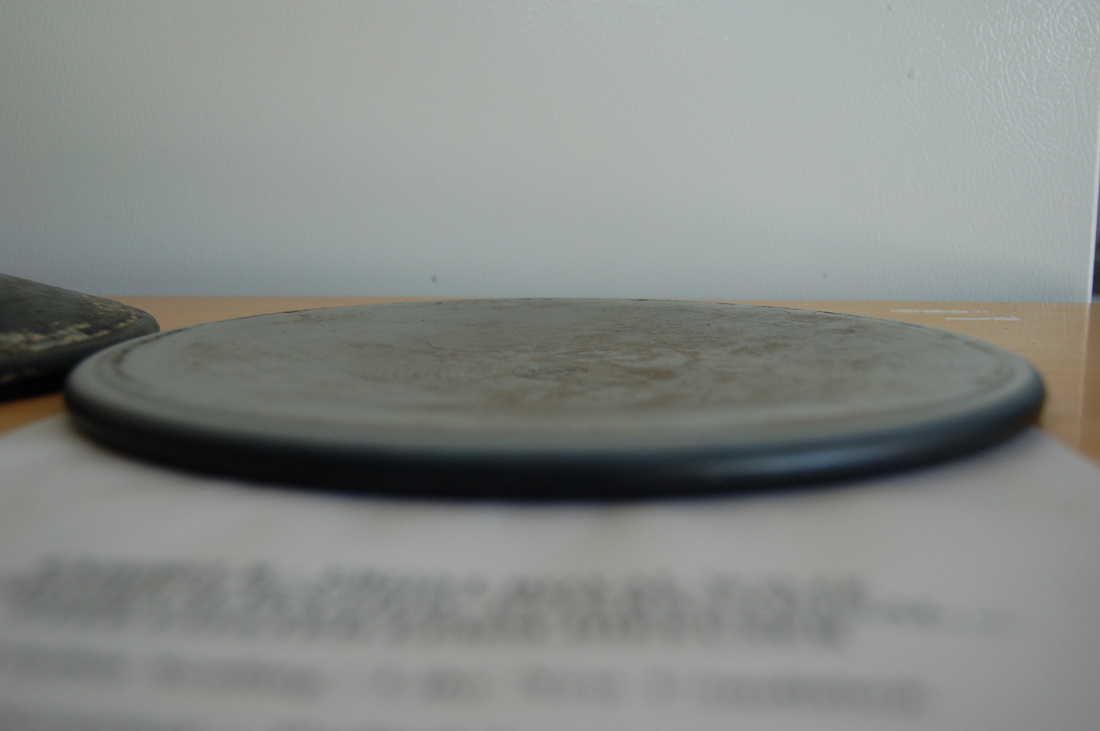

SSI has set themselves apart in the marketplace with their R&D in specialty Coatings. They have pioneered and patented technology that prolongs the effective life and oxygen transfer efficiency well beyond standard EPDM, resulting in significant life cycle energy and maintenance savings. Standard EPDM membrane failure occurs well before physical rupture of the membranes. Plasticizer leach into the liquid stream causes unrecoverable creep and cause irreversible loss of oxygen transfer efficiency. Protecting the EPDM with chemically bonded coatings limits this leaching and protects the diffusers from failure issues. The picture of the two membranes was taken by a customer with a competitors membrane, both in service for the same time. The PTFE coated EPDM diffuser required no cleaning, the competitors diffuser had been scrubbed and still met the owners definition of failure in their system.

EPDM

EPDM is a synthetic rubber which is custom molded for this application. The compound formulation and molding technique are critical to ensure that the membrane maintains its physical properties over a long period of time, resists tearing, retains its shape even after years of continuous or cyclical use, and produces fine bubbles, all at a minimal head pressure. Our EPDM membranes are field tested in municipal and industrial applications with excellent results.

Standard EPDM is not recommended in cases where solvents, fats oils or greases, or high concentrations of other foulants are present. membranes are field tested in municipal and industrial applications with excellent results.

EPDM is a synthetic rubber which is custom molded for this application. The compound formulation and molding technique are critical to ensure that the membrane maintains its physical properties over a long period of time, resists tearing, retains its shape even after years of continuous or cyclical use, and produces fine bubbles, all at a minimal head pressure. Our EPDM membranes are field tested in municipal and industrial applications with excellent results.

Standard EPDM is not recommended in cases where solvents, fats oils or greases, or high concentrations of other foulants are present. membranes are field tested in municipal and industrial applications with excellent results.

PTFE

Developed in 2004, and protected by patent thereafter, the PTFE-coated EPDM membrane is now proven technology. SSI pioneered and patented the use of thin film surface layers of Fluoroelastomers permanently joined to the surface of an EPDM or other substrate base material. Industrially, this product is a "must have", and has become the industry standard in pulp and paper, dairy, refinery, carbonated beverage, and landfill leachate applications. Municipally, it is used by major cities worldwide due to the anticipated life cycle cost benefits and reduced maintenance.

For more information on our PTFE product visit this page.

Developed in 2004, and protected by patent thereafter, the PTFE-coated EPDM membrane is now proven technology. SSI pioneered and patented the use of thin film surface layers of Fluoroelastomers permanently joined to the surface of an EPDM or other substrate base material. Industrially, this product is a "must have", and has become the industry standard in pulp and paper, dairy, refinery, carbonated beverage, and landfill leachate applications. Municipally, it is used by major cities worldwide due to the anticipated life cycle cost benefits and reduced maintenance.

For more information on our PTFE product visit this page.

fEPDM™

fEPDM™ membranes were developed in 2007 as an answer to those few cases where solvents were present and posed a risk to PTFE-coated membranes. In practice, they have outstanding chemical resistance similar to Viton®. A significant additional benefit of fEPDM™ membranes is that the entire outer surface area of the membrane is protected. This proprietary process also treats and protects the inner slits!

fEPDM™ membranes were developed in 2007 as an answer to those few cases where solvents were present and posed a risk to PTFE-coated membranes. In practice, they have outstanding chemical resistance similar to Viton®. A significant additional benefit of fEPDM™ membranes is that the entire outer surface area of the membrane is protected. This proprietary process also treats and protects the inner slits!

Viton ®

This material has been used successfully by SSI in a few applications where budget constraints were not an issue. The membrane works very well, and is highly resistant to most foulants and chemicals. Viton® typically costs 10x the cost of EPDM membranes.

This material has been used successfully by SSI in a few applications where budget constraints were not an issue. The membrane works very well, and is highly resistant to most foulants and chemicals. Viton® typically costs 10x the cost of EPDM membranes.

Webbed Urethane

Developed in 2009 with patent protection filed for in 2010, SSI's webbed polyurethane membrane provides outstanding chemical resistance and excellent creep resistance. Available with either standard or micro perforations to produce fine or ultra fine bubbles, this membrane material is suitable for municipal or industrial service.

Developed in 2009 with patent protection filed for in 2010, SSI's webbed polyurethane membrane provides outstanding chemical resistance and excellent creep resistance. Available with either standard or micro perforations to produce fine or ultra fine bubbles, this membrane material is suitable for municipal or industrial service.

Silicone

SSI does produce silicone discs and tubes, as well as polyurethane tubes, however we much prefer the characteristics of the fluoroelastomer layered membranes, since both silicone and polyurethane have a tendency over time to suffer from tearing due to flexure failure, which is something that does not significantly afflict EPDM membranes. Neither polyurethane nor silicone is suited to cyclical operation, and neither offers a cost benefit over fluoroelastomer layered EPDM membranes.

SSI does produce silicone discs and tubes, as well as polyurethane tubes, however we much prefer the characteristics of the fluoroelastomer layered membranes, since both silicone and polyurethane have a tendency over time to suffer from tearing due to flexure failure, which is something that does not significantly afflict EPDM membranes. Neither polyurethane nor silicone is suited to cyclical operation, and neither offers a cost benefit over fluoroelastomer layered EPDM membranes.

Fine Bubble Diffusers (Hover over image for Details)

Coarse Bubble Diffusers (Hover over image for Details)

Aeration System Accessories (Hover over image for Details)

Replacement Disc Diffuser Membranes

SSI is the leading aftermarket manufacturer of replacement membranes for other diffuser brands. Diffuser membranes are produced with the same high quality materials used to produce their own products and their patent pending PTFE or Viton™ layered EPDM is available as an option.

Their membranes are field tested in municipal and industrial applications with excellent results.

Products by Manufacturer:

Their membranes are field tested in municipal and industrial applications with excellent results.

Products by Manufacturer:

- Sanitaire™ Replacement brand disc diffusers (ceramic or membrane replacement).

- EDI™ Replacement brand disc diffusers.

- Nopon™ SSI manufactures disc retrofit membranes for both 215 and 300 sized diffusers.

- Roediger™ brand disc diffusers.

- Envicon™ SSI manufactures disc retrofit membranes for both 215 and 300 sized diffusers.

- Envirex™ 20”/Nopon 500mm dia discs

- Degremont™

- US Filter/Envirex™

- Ecologix™

- Aercor™

Replacement Tube Diffusers

Products by Manufacturer:

SSI is not affiliated with any of the above companies and the products they manufacture to retrofit these brands are neither original OEM equipment nor are they specifically approved for use by these manufacturers.

Read More...

- Gummi Jaeger ™

- Envicon ™

- Rehau™

- OTT™

- EDI™

- Supratec ™

- Degremont ™

- US Filter/Envirex ™

- Ecologix ™

- Wyss ™

- Aqua Aerobics ™

SSI is not affiliated with any of the above companies and the products they manufacture to retrofit these brands are neither original OEM equipment nor are they specifically approved for use by these manufacturers.

Read More...