MECHANICAL AERATION

Lagoons, Activated Sludge, Flow retention basins, SBR's and digesters. Jet, floating, wall mount, bottom fixed and bridge mounted. Mechanical aeration (and mixing) technologies still have a solid place and application in the water/wastewater industry. WE can help find the best technology for your application. WE feature technologies to achieve all ends. Please look specifically at the Hyperbolic Mixer by Aquatubo. This technology was identified by USEPA as new and upcoming green technology. Available as both mix and mix/aeration units, air flow can be controlled independent of mixing action and for very low horsepower.

|

Fluidyne Jet Aeration provides an economical and effective approach to oxidizing and mixing wastewater. Jet Aeration Systems are ideal for both industrial and municipal activated sludge processes including SBRs, oxidation ditches, extended aeration and BNR. Due to their flexibility, large solids handling capability and efficiency, jets are also commonly used in aerobic digesters, sludge holding tanks, flow equalization basins and post aeration tanks.

INNOVATIVE DESIGN Jet mixing employs an arrangement of either jets or ejectors, each a jet nozzle, to entrain a large volume of liquid, using a small amount of pumped fluid or gas. This innovative systems produces extremely high mixing rates and strong fluid movement using very little energy. COST EFFECTIVE & EASY TO MAINTAIN It’s far simpler, far less costly and far easier to maintain than other aeration and mixing methods including fine bubble diffusers, coarse bubble diffusers and surface type aerators. In a Fluidyne jet aeration and mixing manifold, there are no moving parts, bearings or metal components submerged in the liquid. The only moving parts are the pump or compressor located outside the liquid tank or basin. A built-in back-flush assembly allows cleaning the manifold without entering the tank. The units are standard models backed by quickly available service. WELL CONSTRUCTED Submerged components of a Fluidyne system, the nozzle and piping, are built of corrosion and abrasion resistant stainless steel or fiberglass reinforced polyester. Read More... |

|

Aquaturbo Systems, Inc., manufactures a wide range of mechanical aeration and aeration/mixing devices to meet your needs.

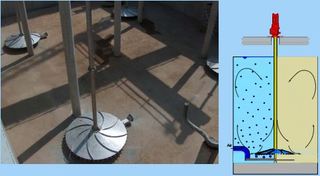

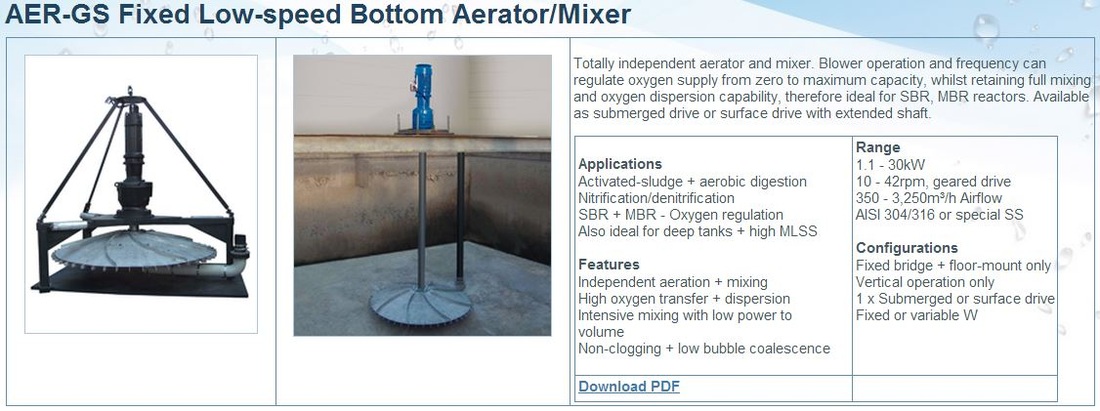

The Aer-GS is a low speed submersible aerator / mixer. The unit is available as a bridge mount or submersible configuration. This technology was recognized as green mixing technology by EPA. The units large stainless base an slow rotation provides a high degree of mixing with very little horsepower. The air supply can be independent of mixing offering infinite combinations of aeration and mixing. Click the image below for more information

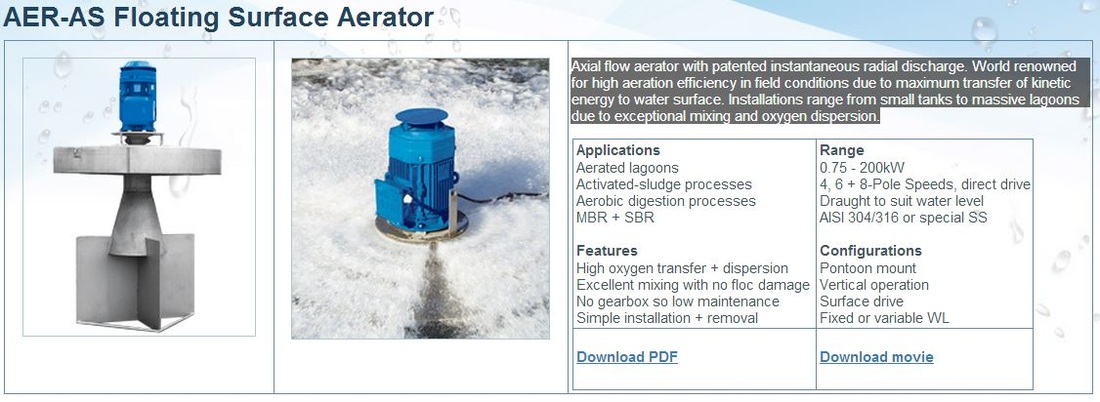

Axial flow floating aerator with patented instantaneous radial discharge. World renowned for high aeration efficiency in field conditions due to maximum transfer of kinetic energy to water surface. Installations range from small tanks to massive lagoons due to exceptional mixing and oxygen dispersion. Click the image below for more information Read more...

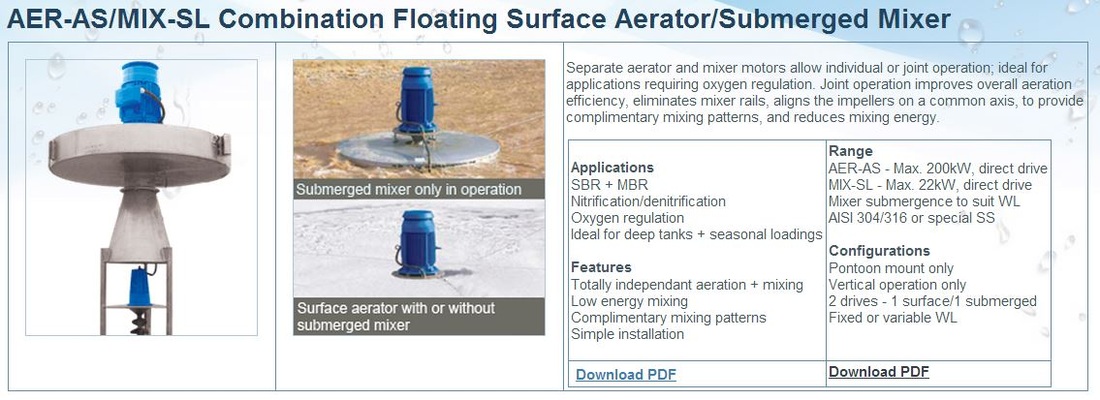

Floating system with separate aerator and mixer motors allow individual or joint operation; ideal for applications requiring oxygen regulation. Joint operation improves overall aeration efficiency, eliminates mixer rails, aligns the impellers on a common axis, to provide complimentary mixing patterns, and reduces mixing energy. Click the image below for more information Read more...

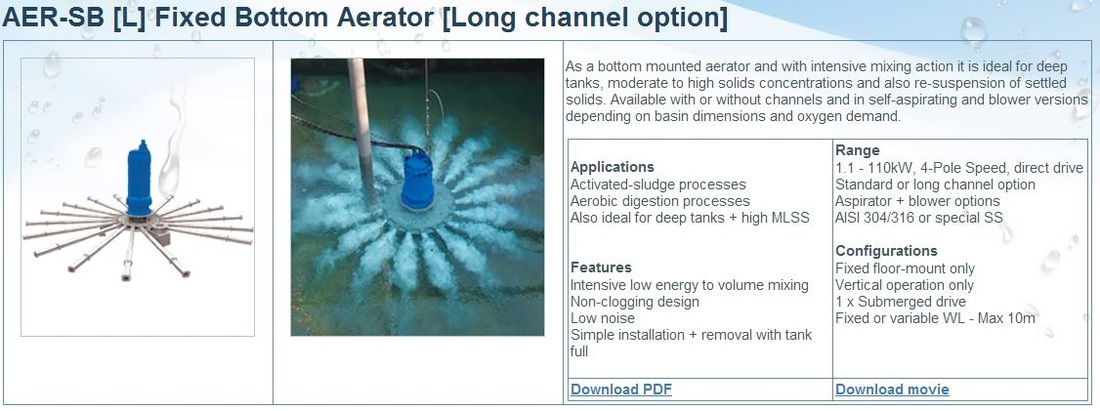

As a bottom mounted aerator and with intensive mixing action it is ideal for deep tanks, moderate to high solids concentrations and also re-suspension of settled solids. Available with or without channels and in self-aspirating and blower versions depending on basin dimensions and oxygen demand. Click the image below for more information Read more...

Floating or Rail Mount aspirator aerator featuring a unique impeller and vacuum chamber design drawing air below water level and dispersing as micro-bubbles in any chosen direction. Ideal when aeration and directional flow generation are required in a single unit. Multiple mounting options allow use in any basin geometry. Click the image below for more information Read more...

Specifically designed for fixed mounting to allow impeller immersion to vary in accordance with flow and associated oxygen demand. Maintains aeration efficiency at variable speed. Four impeller options - 4-blade, to induce circulation in oxidation ditches, and 6-blade, for higher efficiency; LH or RH. Click the image below for more information Read more...

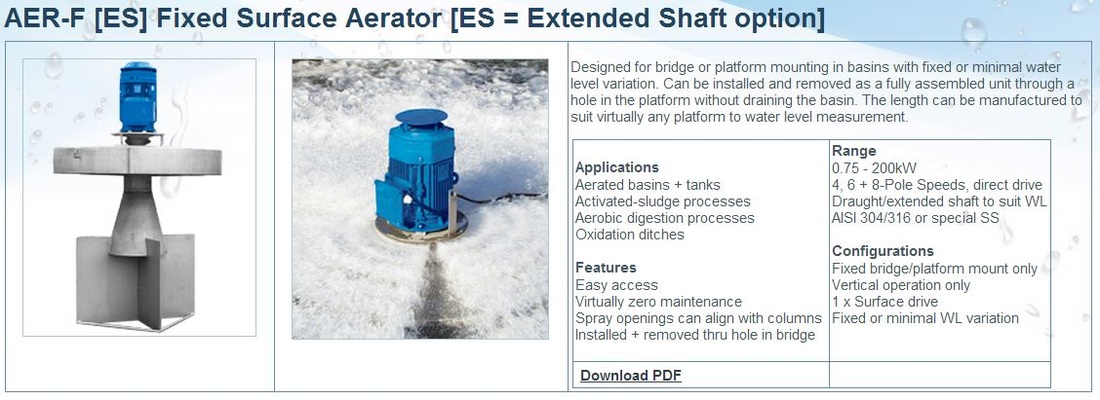

Designed for bridge or platform mounting in basins with fixed or minimal water level variation. Can be installed and removed as a fully assembled unit through a hole in the platform without draining the basin. The length can be manufactured to suit virtually any platform to water level measurement. Click the image below for more information Read more...