MIXING

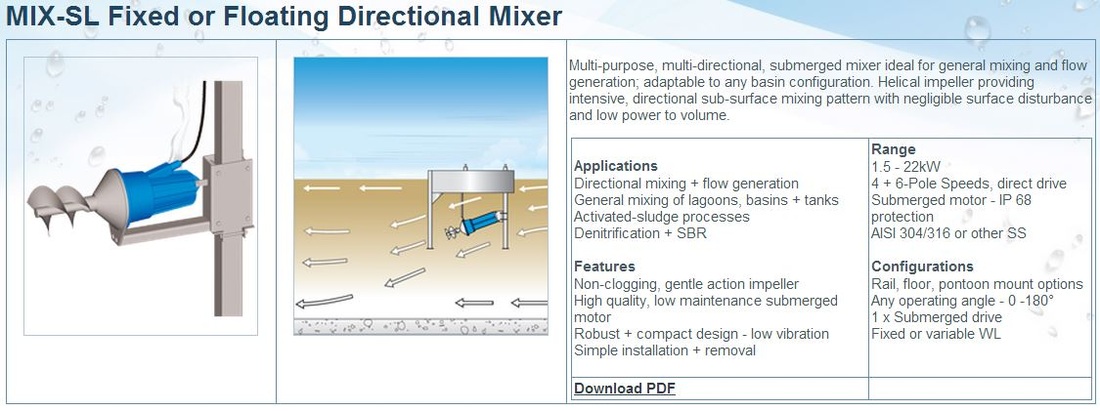

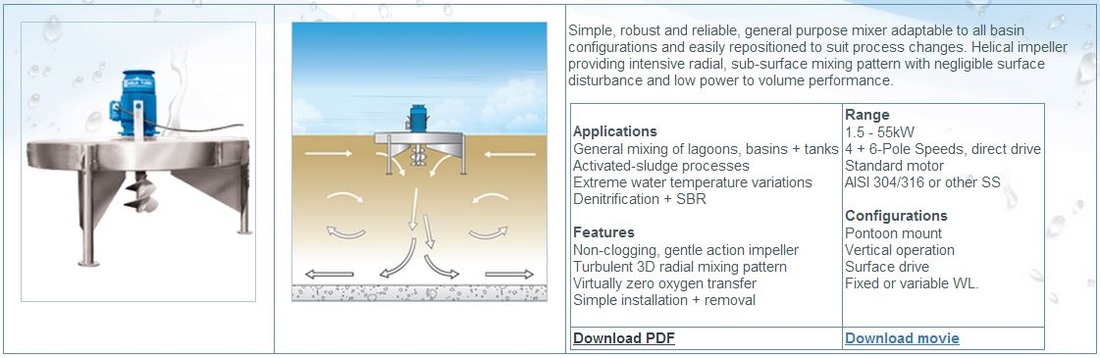

Lagoons, Activated Sludge, Flow retention basins, SBR's and digesters. Jet, floating, wall mount, bottom fixed and bridge mounted. Mechanical mixing technologies still have a solid place and application in the water/wastewater industry. WE can help find the best technology for your application. WE feature technologies to achieve all ends. Please look specifically at the Hyperbolic Mixer by Aquatubo and the Pulsair Megabubble mixing system. These technologies were identified by USEPA as innovative green technologies. With the Aquaturbo unit available as both mix and mix/aeration units, air flow can be controlled independent of mixing action and for very low horsepower.

Pulsair Systems Inc - Mega-bubble Liquid Mixing Systems

|

The NSF certified Pulsair system is a perfect solution to your mixing needs. The "non-aerating" air bubble is perfect for everything from water storage tank mixing to anoxic mix tanks. The benefits are much lower costs for both capital and operation, no moving parts within the process liquid and very effective low energy mixing. The system is up to 95% more energy efficient than mechanical mixers, suitable for any tank size and can uniformly mix 100% of tanks contents at any fluid level

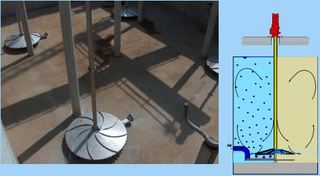

Pulsair's technology is a "pulsed air technology" process which is the sequential release of compressed air or gas at the bottom of a tank, vessel or basin for the purpose of creating circulation and mixing. Measured amounts of high pressure air or gas are "pulsed" under flat round discs called accumulator plates installed on the tank bottom. This sudden release of air shocks the liquid, setting molecules in motion. As the air "squeezes out" between the plate and tank floor, it sweeps out the heavier liquids and solids. The air then accumulates above the plate into very large, single oval shaped bubble. The bubble rises to the surface, a vacuum is created that pulls the heavier bottom liquids and solids up with it. As the bubble rises it also pushes the liquid above it up and out towards the tank perimeter. The liquid moves toward the sides of the tank and travels down the tank wall to the bottom. With no moving parts and minimal maintenance, pulsed air technology significantly reduces the need for maintenance and the associated costs and downtime. Learn more about the Pulsair Mix system |

How the Pulsair system works

|

|