SOLIDS DEWATERING

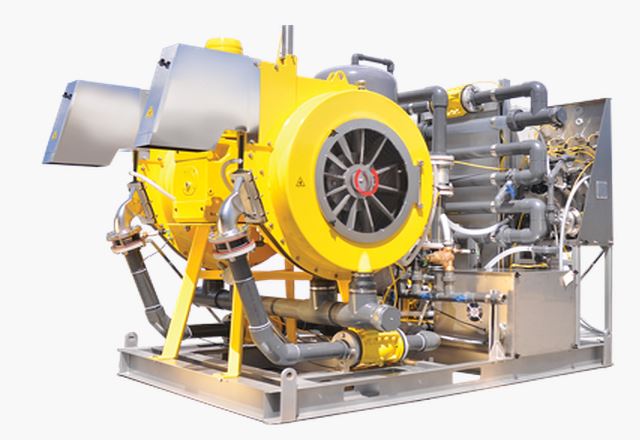

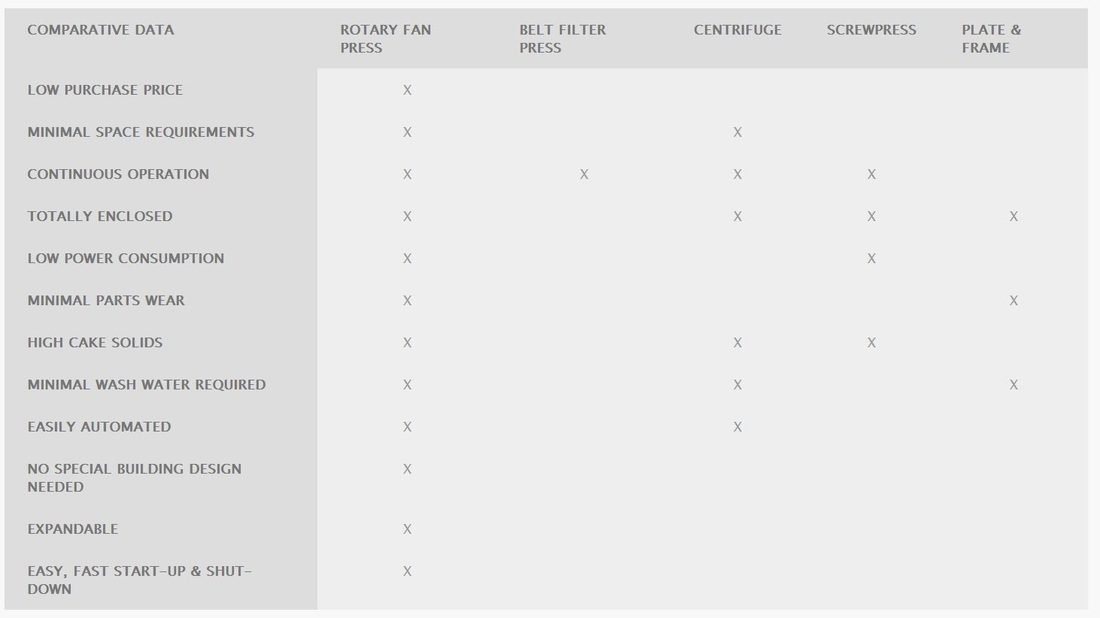

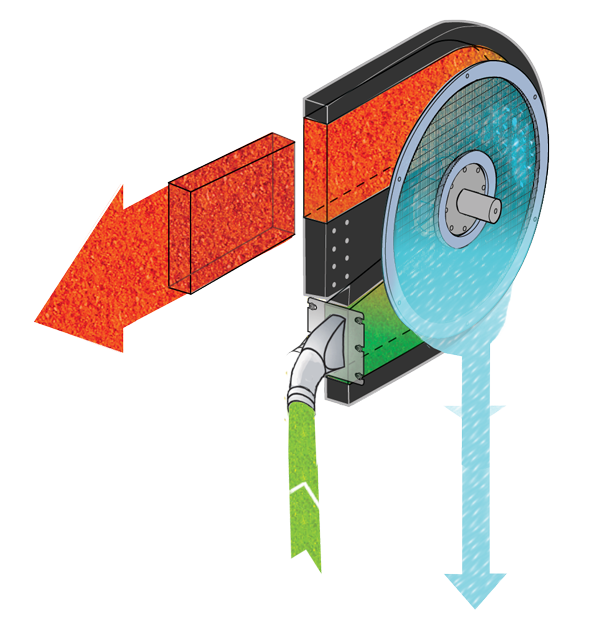

Biosolids dewatering operations have a huge impact on the plant. WE have the technology and the capability to help you select and support your operations. WE can help determine the most appropriate technology. WE can do polymer testing, selection and sales. WE can supply pumps, polymer systems, and conveyors to go along with your systems and WE know how to integrate it all. Whether you are looking to retrofit, replace or expand WE have systems to meet your needs. Belt press, rotary press, or screw press, WE can help you select the most appropriate technology for your system.

|