Peristaltic Pumps

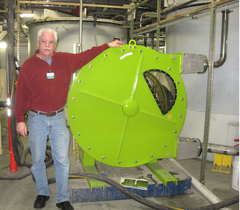

Flo Motion ALH Series Industrial Hose Pumps High Capacity Industrial Hose Pump

The ALH Series of peristatlic pumps provide high levels of volumetric accuracy for sampling and metering applications. ALH Series pumps are available in 15 different sizes that provide flow rates up to 38,000 GPH. The low maintenance, seal-less design eliminates leaks, contamination and wear problems associated with difficult to seal products.

Only the inside of the hose and hose inserts are in contact with the aggressive and contaminated fluids. This means that they can be processed without attacking the rest of the pump components as often happens with other pumping technologies. They have the ability to pass solids in the material being pumped as large as 20% of the hose ID. Dry-run capability and self-priming up to 32 ft. allows tank and line stripping. Will handle fragile fluids with little wear.

ALH Series hoses are compatible with many other manufacturers pumps. Hoses are constructed of natural rubber, NBR, EPDM, Hypalon, FKM. Reversible operation allows pumping in both directions and durable construction of ductile iron and steel construction allow higher discharge pressures up to 217 psi.

Features of the Flo Motion ALH Series Include:

Only the inside of the hose and hose inserts are in contact with the aggressive and contaminated fluids. This means that they can be processed without attacking the rest of the pump components as often happens with other pumping technologies. They have the ability to pass solids in the material being pumped as large as 20% of the hose ID. Dry-run capability and self-priming up to 32 ft. allows tank and line stripping. Will handle fragile fluids with little wear.

ALH Series hoses are compatible with many other manufacturers pumps. Hoses are constructed of natural rubber, NBR, EPDM, Hypalon, FKM. Reversible operation allows pumping in both directions and durable construction of ductile iron and steel construction allow higher discharge pressures up to 217 psi.

Features of the Flo Motion ALH Series Include:

- Flow rates from 0.02 to 387 GPM (1 to 23,220 GPH).

- Outlet Pressures to 217 psi.

- Fully self-priming up to 32 ft.

- No mechanical seal or stuffing box.

- Suitable for aggressive or viscous fluids.

- Metering of very corrosive chemicals.

- Damage-free continuous dry running.

- Adjustable flow output with VFD controller.

- Inverter Duty, Explosion-Proof and Chemical-Duty motor options.

- Very easy maintenance.

- Heavy-duty bearings, greased for life.

- Two-year warranty.

- Bidirectional operation.

- Close coupled, compact footprint.

- Low sound level: < 70 dB at 3 ft.

Flo Motion ALP Series Industrial Hose Pumps

The ALP Series is a two roller Peristaltic pump designed to handle abrasive slurries, viscous fluids, and aggressive chemicals that are normally difficult to pump with other types of positive displacement technologies. The ALP Series is an ideal choice for metering, batching and transfer applications. Peristaltic pumps are becoming the standard for hard to handle fluids such as Sodium Hypochlorite that off-gas and vapor-lock diaphragm pumps. Five models are available that offers a wide range of flow rate outputs. Newer hose materials offer better chemical resistance and longer life in demanding applications.

Only the inside of the hose and hose inserts are in contact with the aggressive and contaminated fluids. This means that they can be processed without attacking the rest of the pump components as often happens with other pumping technologies. They have the ability to pass solids in the material being pumped as large as 20% of the hose ID. Dry-run capability and self-priming up to 20 ft. allows tank and line stripping. Will handle fragile fluids with little wear.

ALP Series hoses are compatible with many other manufacturers pumps. Hoses are constructed of natural rubber, EPDM, Buna N, Norprene, Tygoprene, Nitrile, Silicone. Reversible operation allows pumping in both directions.

Features of the Flo Motion ALP Series Include:

Only the inside of the hose and hose inserts are in contact with the aggressive and contaminated fluids. This means that they can be processed without attacking the rest of the pump components as often happens with other pumping technologies. They have the ability to pass solids in the material being pumped as large as 20% of the hose ID. Dry-run capability and self-priming up to 20 ft. allows tank and line stripping. Will handle fragile fluids with little wear.

ALP Series hoses are compatible with many other manufacturers pumps. Hoses are constructed of natural rubber, EPDM, Buna N, Norprene, Tygoprene, Nitrile, Silicone. Reversible operation allows pumping in both directions.

Features of the Flo Motion ALP Series Include:

- Flow rates from 1 to 40 GPM (60 to 2400 GPH).

- Outlet Pressures to 60 psi.

- Fully self-priming up to 20 ft.

- No mechanical seal or stuffing box.

- Suitable for aggressive or viscous fluids.

- Metering of very corrosive chemicals.

- Damage-free continuous dry running.

- Adjustable flow output with VFD controller.

- Inverter Duty, Explosion-Proof and Chemical-Duty motor options.

- Very easy maintenance.

- Heavy-duty bearings, greased for life.

- Two-year warranty.

- Bidirectional operation.

- Close coupled, compact footprint.

- Low sound level: < 70 dB at 3 ft.

Flo Motion 2001H Series Compact Industrial Hose Pumps

Exceptional self-priming capabilities make the 2001H Series peristaltic pumps an ideal choice for hard-to-handle chemicals such as sodium hypochlorite, hydrogen peroxide or viscous polymers. An extremely wide range of flow outputs can be obtained by simply changing the tubing size.

The versatile NEMA 4X motor drive controller may be conveniently mounted directly on the pump or remotely on a wall or panel. One size pumphead accepts six standard tubing sizes. The spring loaded pumphead rollers provide extended tubing life and automatically compensate for minor variations in pump tube wall thickness.

An optional tubing rupture detector will automatically shut down the 2001HEC pump and signal an alarm in the event of a tubing leak. Used in conjunction with the unique 2001H sealed pump design the FLOMOTION Tubing Rupture Detector helps to protect operators and other equipment from potentially dangerous fumes and chemicals.

Features of Flo Motion 2001H Series Include:

The versatile NEMA 4X motor drive controller may be conveniently mounted directly on the pump or remotely on a wall or panel. One size pumphead accepts six standard tubing sizes. The spring loaded pumphead rollers provide extended tubing life and automatically compensate for minor variations in pump tube wall thickness.

An optional tubing rupture detector will automatically shut down the 2001HEC pump and signal an alarm in the event of a tubing leak. Used in conjunction with the unique 2001H sealed pump design the FLOMOTION Tubing Rupture Detector helps to protect operators and other equipment from potentially dangerous fumes and chemicals.

Features of Flo Motion 2001H Series Include:

- Flows to 50.2 GPH, Pressures to 100 psi.

- Seal-less pumping technology.

- Self-priming - suction lifts to 30 ft.

- NEMA 4X controller.

- No check valves - few moving parts.

- Various long life chemical resistant tubing options available.

- Dry run capability.

- LED digital display & integral keypad.

- User selectable manual or automatic control.

- Automatic control via 0-10VDC, 4-20mA.