Tertiary Wastewater Filtration

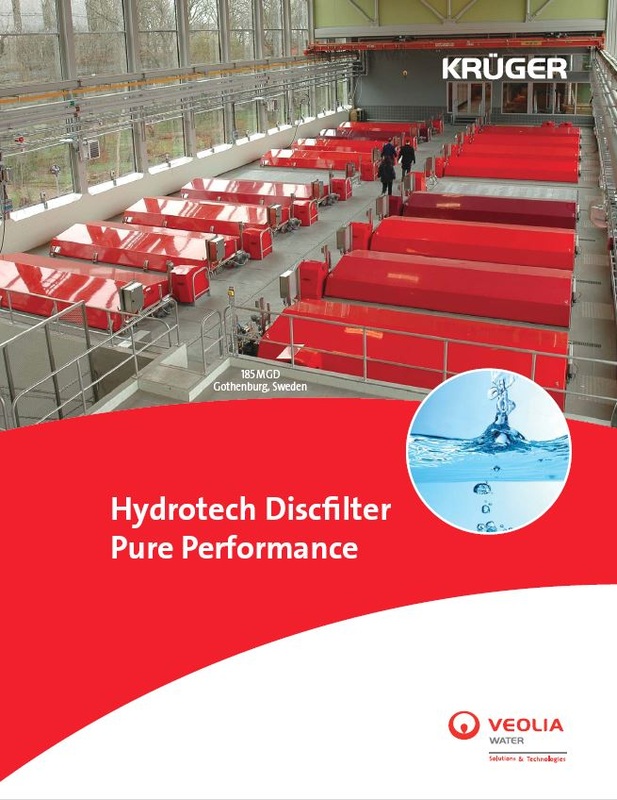

Kruger Hydrotech Disc Filter The Hydrotech Discfilter provides an ideal filtration system for fine solids removal. By employing woven cloth filter elements installed on multiple discs, and utilizing an inside-out flow pattern, this versatile filter is appropriate for a variety of applications including tertiary wastewater filtration, water reuse, Phosphorus removal, membrane pre-treatment, and stormwater treatment.

Water to be treated flows by gravity into the filter segments from the center drum. The media mounted on both sides of the partially-submerged discs separates the solids from the water.The filtered water flows through the disc media into the collection tank. Once solids have accumulated on the inside of the media, the discs are cleaned by the counter-current backwash system. Benefits

Learn more about the Kruger Hydrotech Discfilter here: Kruger Hydrotech Drum Filter The drumfilter employs woven cloth filter elements installed on the periphery of the drum, and utilizes an inside-out flow pattern. As with the Hydrotech Discfilter, the drumfilter technology is appropriate for a variety of applications including tertiary wastewater filtration, water reuse, Phosphorus removal, membrane pre-treatment, stormwater treatment, and primary influent treatment

Water to be treated flows by gravity into the filter via the center drum. The media mounted on the partially-submerged drum separates solids from the water.The filtered water flows through the media into the collection tank. Once solids have accumulated, the media is cleaned by the counter-current backwash system.The filters are in continuous operation even during backwash and high solids events. Benefits

Learn more about the Kruger Hydrotech DrumFilter here: Actiflo for Wastewater Treatment Applications Shortly after the development of the ACTIFLO® process for drinking water treatment in the early 1990's, investigations into the use of the process for wastewater treatment applications began.With its exceptional solids removal capabilities, the ACTIFLO®process can be utilized in any wastewater application that needs solids separation to include treating wet weather flows, phosphorus removal and water re-use to name a few.The ACTIFLO® process utilizes microsand as a seed for floc formation which later acts as a ballast or weight. The resulting sand ballasted floc, display unique settling characteristics, which allow for clarifier designs with high overflow rates and short retention times. These designs result in system footprints that are between 5 and 20 times smaller than conventional clarification systems of similar capacity.

Learn more about the Kruger Actiflo for Wastewater Treatment |

Download the Hydrotech Discfilter Brochure Here

|